Orca Slicer Calibration for Best 3D Printing Results (2025)

Take your 3D printing to the next level with Orca Slicer Calibration! Fine-tune every detail for flawless results. Start creating perfection today with orca slicer

Why Calibration Needed?

We all know that in 3D printing, the calibration of your printers also matters a lot, along with exceptional design, right? This is because precision and reliability are the main points for creating stunning and functional models. You can machine all this by properly calibrating your printers.

Now, the main concern is how to calibrate your 3D printers. My friend, you will find hundreds of apps or software programs on the internet. But I would suggest you use OrcaSlicer calibration to create flawless prints and designs.

With this tool, you don’t have to hassle with downloading hundreds of other tools. It is because it offers everything in a single place, like Z-axis adjustment, extrusion and temperature settings, and much more. With all these features, you can fine-tune your every print.

What is the Orca Slicer Calibration?

OrcaSlicer Calibration is a tool with rich features that you will find in the Orca Slicer software. This tool was designed to optimize the performance of all 3D printers.

I know, just like me, many of you have heard the word calibration for the first time, right? So, my friend! Calibration refers to making essential adjustments in the printers to gain more accuracy in dimensions, layer adhesion, and overall print quality.

Moreover, this tool is super easy to use due to its simple and user-friendly interface. In the calibration menu, you will find all the options to make adjustments to your designs and prints.

Features of OrcaSlicer Calibration

Some amazing features of Orca Slicer 3D printing software are discussed below. Let’s have a look at these features.

Customizable Printer Profiles

One of the amazing features that you can enjoy is a customizable printer profile. Want to know how it works or what’s its benefit? So, with this feature, every time you switch to a new setup, material, or printer, you don’t need to start from scratch.

It is because this tool offers you an option to create and save your custom printer profile. So, next time, you just need to make some adjustments and start your work.

No matter if you want a high-speed profile for PLA or a high-detail one for PETG. With this feature, you will have access to everything.

Temperature Control

Achieving the perfect prints depends on various factors, right? One of these major factors is maintaining the right temperature. This amazing OrcaSlicer tool helps all the technicians to perfectly maintain the nozzle and bed temperature.

It enables the temperature of each filament to be accurate for the printing process. The exact temperature control will save you from printing failures and also improve layer adhesions.

Layer Height Adjustment

OrcaSlicer also helps to adjust the height of the layer depending on your needs or design requirements. For example, if you want to create a delicate and sensitive design, you should reduce the layer height for precision.

Whereas, if you are making less complex designs, then you can increase the height of the layer. With this flexibility in layer height, you can easily fine-tune your prints and enhance printing with thicker layers.

Real-Time Preview

Now, no need for more guesswork or errors in printing. Yes! This is possible with the help of OrcaSlicer G-code preview. This preview option allows you to visualize your prints and designs before even their printing. Do you know this feature has saved a lot of money and human work?

You can examine each layer’s details, travel paths, and much more. Real-time preview ensures that you will get the best results in the end.

Multi-Extruder Support

Are you using printers on a professional level? And facing dealing with multi-extruder printers? Then don’t worry! It is because OrcaSlicer helps you to support the multi-extruder printers smoothly.

With its expert programming, you can easily adjust the settings of multiple materials and colors and enhance your printing game. Basically, it uses advanced-level calibration tools that will help to align producers and easily transition between designs and materials.

Compatibility with Various 3D Printers

Another amazing feature of this tool is that it is compatible with various 3D printers. So, when you are installing it, you will not face issues of printer compatibility. From some old models of printers to the advanced ones, this tool works perfectly fine on all.

Want to know how this tool is compatible with all printers? So, basically, it has built-in preconfigured printer profiles, which include more than a hundred printers in it. So, what you have to do is just install the tools, select the printer type, and start printing your new designs.

Advanced Calibration Tools

To provide you with the best and finest quality designs, OrcaSlicer provides an extensive range of calibration tools. Each tool in it contains specific features that help enhance your design quality.

Some of these tools include retraction distance, flow rate, and extrusion multiplier. You should understand these tools and their specific role in the world of 3D printing.

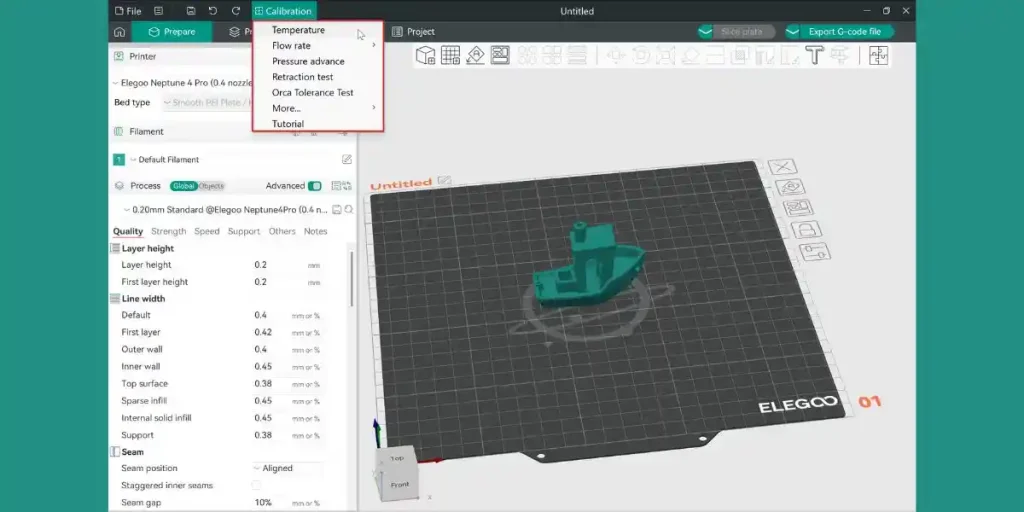

Exploring OrcaSlicer Calibration Menu

With the OcraSlicer Calibration Menu, you will be able to adjust the settings of your 3D printers for best results. This menu consists of a set of tools that will fine-tune and enhance your prints and add precisions.

Moreover, this menu is easy to use for everyone. No matter if you are a new or expert in the field you can easily do printer calibrations for high-quality and accurate results.

Let’s explore some of the main tools in the calibration menu:

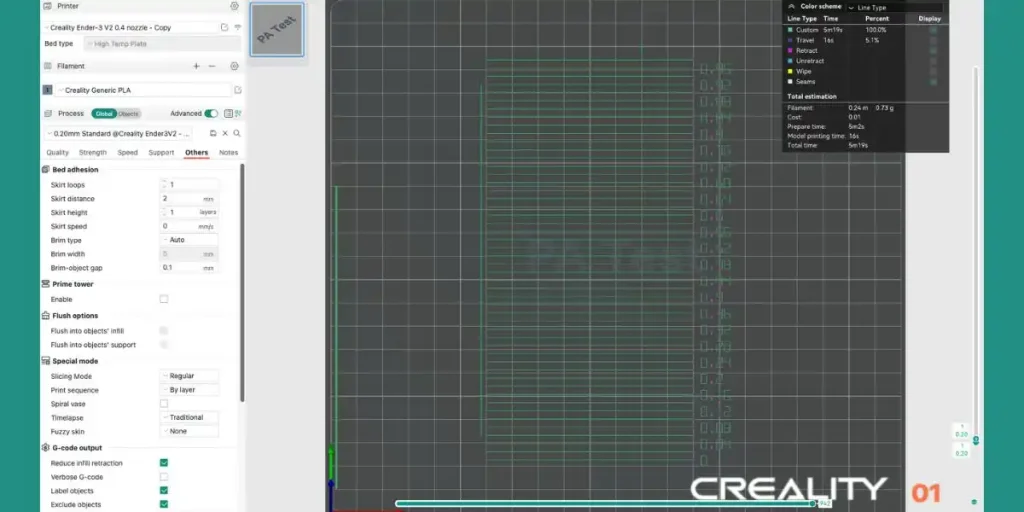

G-code preview and analysis

With the G-code preview and analysis tool, you can easily visualize the G-code generated by the Orcaslicer before printing. By using this tool, you can analyze print paths, travel moves, and support placements.

So that if there are any issues with the design or printing, you can correct them before it is too late.

You should analyze layer-by-layer to identify even smaller errors in printing, such as gaps in infills, overhands, and much more.

Flow Rate

The flow rate will help you to know the optimum amount of filament extruding from the nozzle during the printing process. With these settings, you can avoid under or over-extrusion of filaments.

Adjusting the flow rate is important as it saves you from many design issues. Moreover, it also ensures your prints are smooth, have accurate dimensions, and reduce print defects like gaps or bulges.

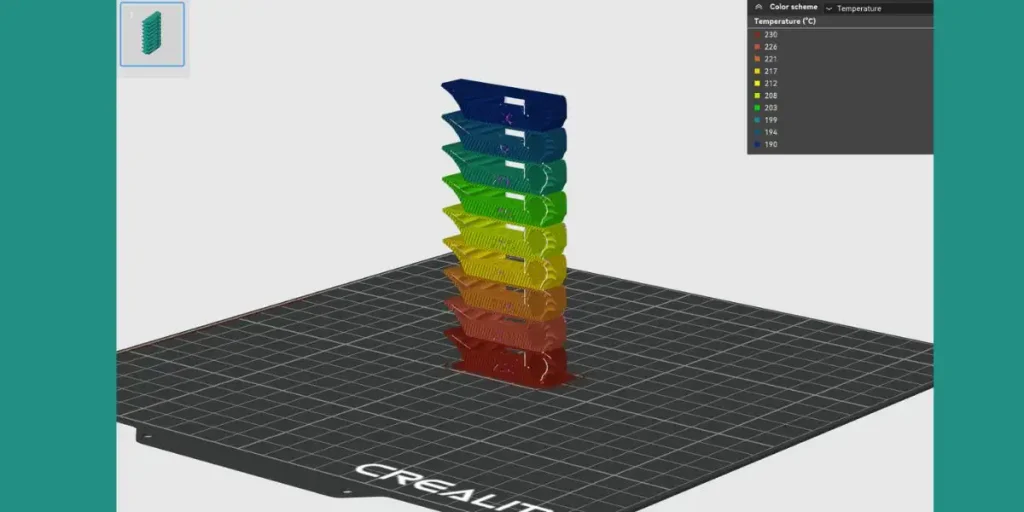

Temperature Tower

The temperature tower helps us to test the effects of extruders’ temperature on the print. In the tower, each section is printed at a different temperature; this will help you find the optimal temperature settings for your filament.

With this temperature tower, you can access adhesion, stringing, and surface finish so that you can alter these factors and choose the best quality for your prints.

Pressure Advance

This amazing tool will adjust how the printers will adjust the extrusion flow during sudden changes in printing, such as at the start and end of the printing process.

If you do not use this tool, you may have to face issues like ends with blobs and uneven transitions. All this will affect the aesthetic appeal of your designs.

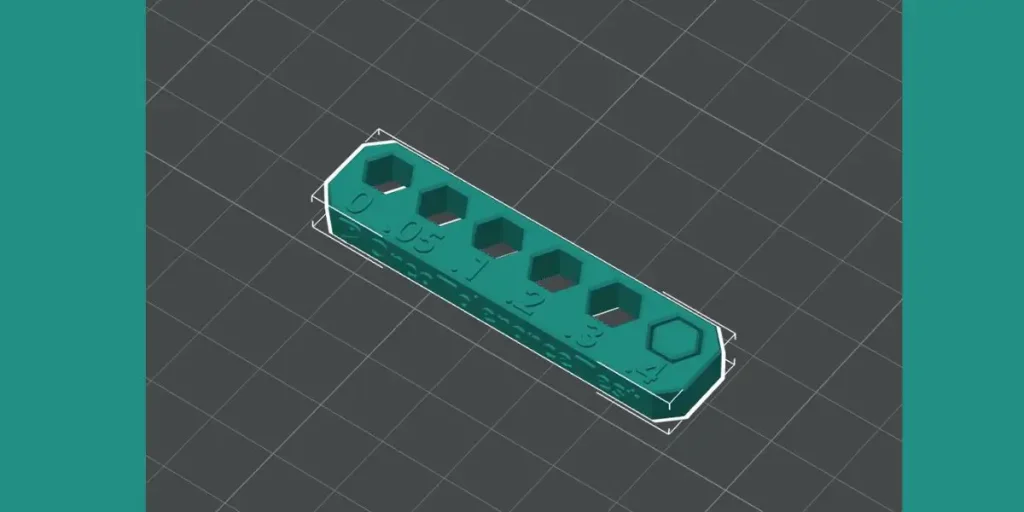

Tolerance Test

The tolerance test is performed to check your printer’s ability to tolerate tight tolerance. To perform this test, users print various geometric shapes with varying dimensions.

After performing this test, you can calibrate your printer’s settings to get more accuracy and precision in your prints.

Vertical line Artifact

Facing unknown errors or vertical artifacts in your designs? Then, you should use this vertical line artifact test tool to identify where the vertical artifacts are in your design and their reasons. These may be formed due to defects in extrusion or vibrations during the printing process.

Retraction Test

With the retraction test, you can create a model print to know how much the printer will pull back the filament during the non-printing phase. This test helps you to minimize printing errors. The OrcaSlicer tool adjusts the retraction speed and duration to create a clean print.

Guide of OrcaSlicer Calibration Steps

Here are all the essential steps of calibration through the use of the Orca Slicer 3D printing tool. Follow these steps:

- First of all, you should prepare your printer by installing an extruder, loading the filament, and cleaning the print bed.

- In the next step, you should level the print bed. For this, you can use an automatic or manual print bed leveling system.

- Now, you should set the Z-axis offset. For this, lower the nozzle and then set the Z-axis to zero at the point of contact.

- Then, you should adjust the flow rate from the OrcaSlicer settings.

- Then set the temperature tower and find the optimum temperature level for printing.

- The next most important steps include adjusting the retraction settings and fine-tuning pressure advance.

- Now, the last step comes, which is to design a sample for testing before starting the bulk printing work.

Common Calibration Issues and Troubleshooting

However, we know calibration is essential for creating high-quality 3D prints. But my friend! These prints often come with various challenges.

To achieve more accuracy in your prints, you should understand common issues and find ways to troubleshoot them. This will help to save time, effort, filaments, and frustration, as well.

Here is a list of the most common issues users often face and their solutions:

Poor Bed Adhesion

In this issue, the first layer of print does not stick to the print bed properly, which results in the price failing or wrapping. The common reasons for this issue include:

- The bed was not leveled properly.

- Incorrect Z-offset or nozzle height.

Solution of Poor Bed Adhesion

The solutions to this problem are listed below:

- You should level the bed properly with the help of a sheet of paper or a feeler gauge.

- You should also adjust the Z-offset to adjust the nozzle closer to the bed.

Over or Under-Extrusion

Due to incorrect flow rate settings, Clogged nozzle, or inconsistent filament diameter, the prints show uneven designs. This will make your designs look poor. The solutions to get rid of this issue are listed below.

Solutions

- Using the OrcaSlicer, you should perform the flow rate test before starting the printing process.

- You should also check and clean the nozzle regularly.

- You can also use high-quality filament with a proper diameter.

Clogged or Partially Blocked Nozzle

You will notice that the filament is not extruding from the nozzle evenly. So it creates uneven designs or prints. The causes for this include:

- Dust in the nozzle

- Old filament debris in the nozzle

Solution

The possible solutions to resolve this type of issue are listed below:

- You should clean the nozzle by heating it and then removing all the residue particles.

- You should use a filament filter to avoid dust accumulation.

Why Calibration Needed?

To get flawless and accurate 3D designs, printer calibration is the ultimate process. With the help of calibrations, you can design more fine and attractive prints.

However, you will find a lot of software for calibration, but no one will offer features like the OrcaSlicer calibration tool does. Its user-friendly interface and many advanced printing options, like real-time preview, flow rate adjustment, and custom printer profile, make it unique.